Hard-gold film technology for the realization of low-resistance and high mechanical strength

- researcher's name

- affiliation

-

- research field

-

Device related chemistry,Nanobioscience,Electronic materials/Electric materials

- keyword

-

background

Hard-gold film is used for electronic contact materials including USB terminals, and plays a role for the transfer of information and provision of electricity among analog and digital products. There is a need to improve electronic properties as well as chemical and mechanical qualities beyond the current levels for connection materials.

summary

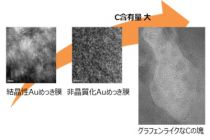

This technology introduces carbon to hard AuNi film, making the structure of the film amorphous, and producing AuNiC film with greatly heightened abrasion resistance without lowering its electric resistance. A technology concerning the manufacturing of AuNiC film.

application/development

A current hard gold film surrogate and next-generation micro-connection film.

predominance

The cost of gold accounts for over 90% of the composition cost of gold coating film. The film used by this project is a thinner film with good mechanical properties, enabling effective cost cutting. In addition, it is possible to apply this technology’s high sustainment of electric transmission to fine connection materials including microscopic connectors. In addition to crystalline and amorphous gold film compositions, by increasing the amount of carbon, this same method can also create grapheme film, as shown in the diagram, and for the creation of nickel carbide film by removing the material’s auric salts.

purpose of providing seeds

Sponsord research, Collaboration research, Technical consultation

material

same researcher's seeds

-

Field Effect Transistor Sensor

Field Effect Transistor Sensor

-

Manufacturing of nano particle array substrates

Manufacturing of nano particle array substrates

-

All Wet ULSI manufacturing process

All Wet ULSI manufacturing process

-

Evaluating lithium-ion battery (LIB) cell degradation using an impedance measurement

Evaluating lithium-ion battery (LIB) cell degradation using an impedance measurement

-

Long-life negative silicon anode synthesis for next-generation lithium-ion batteries

Long-life negative silicon anode synthesis for next-generation lithium-ion batteries

-

Production technology development for the creation of a next-generation laminated lithium-ion battery

Production technology development for the creation of a next-generation laminated lithium-ion battery

-

Monitoring Chemical Balance in Epidermal Barriers

Monitoring Chemical Balance in Epidermal Barriers

-

Development of Biosensing Technology for Food Safety

Development of Biosensing Technology for Food Safety

-

Development of magnetic nanoparticles for cancer care

Development of magnetic nanoparticles for cancer care

-

Chemical Health Monitor Kind to Skin

Chemical Health Monitor Kind to Skin

-

Seeing mental stress from invisible substances

Seeing mental stress from invisible substances

-

Battery Diagnosis by Square-Current Electrochemical Impedance Spectroscopy

Battery Diagnosis by Square-Current Electrochemical Impedance Spectroscopy

posted:

2014/05/21