Increase in thermal energy quality through chemical regeneration

- researcher's name

- affiliation

- research field

-

Thermal engineering,Energy engineering,Catalyst/Resource chemical process

- keyword

-

background

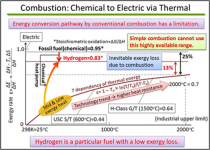

There are demands for higher efficiency in energy conversion, which obtains power and electrical energy from fossil fuels, in order to reduce the emission of greenhouse gases. The theoretical rate of conversion of fossil fuels to work (=exergy rate) is over 90%, but the fact is that much is lost in the combustion process.

summary

While thermal energy can be obtained easily and in large volume, it is irreversible, making it difficult to maintain a high-exergy-rate state. To address this, we can use chemical regeneration. Exergy-lowering processes like vapor reformation and partial oxidation chemically draw out thermal energy at medium-to-low temperature, under which the exergy rate decreases, and through this, the possibility of restoring the high rate is created.

application/development

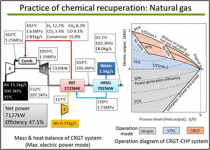

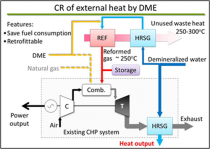

By incorporating methanol, natural gas (methane), DME, bioethanol and other materials used as fuel into heat-recupurated electrochemical partial oxidation and vapor reformation reaction processes, it is possible to apply these methods to fuel cells, chemical regeneration gas turbines, chemical regeneration engines and more.

predominance

Traditional combined power generation and thermal power supply systems mainly used topping cycles at or above 1000ºC and exhaust heat cascades at 500 – 600ºC. In contrast, chemical regeneration technology allows the reuse at over 1000ºC of medium-to-low temperature waste heat of around 300ºC, making it possible to obtain higher energy efficiencies.

purpose of providing seeds

Sponsord research, Collaboration research, Technical consultation

same researcher's seeds

posted:

2014/05/21