Synthesis of Ordered Porous Materials and Catalytic Chemical Applications

2012-1029-01

- researcher's name

-

about researcher MATSUKATA, Masahiko Professor

- affiliation

-

Faculty of Science and Engineering School of Advanced Science and Engineering

- research field

-

Catalyst/Resource chemical process,Properties in chemical engineering process/Transfer operation/Unit operation,Reaction engineering/Process system,Inorganic industrial materials,Nanostructural chemistry

- keyword

-

background

In the 21st century, the issues of energy, resources, and the environment are critical challenges for not only Japan but also the entire globe. To address these issues, the Matsukata Laboratory carries out research on science and engineering pertaining to catalytic chemistry, membrane separation engineering, and the chemistry of energy conversion. The Laboratory lays particular emphasis on the research of the synthesis and catalytic applications of micro- and mesoporous materials, their use as a separation membrane, and the development of purification processes, including for contaminated soil and effluent.

■Research on micro- and mesoporous materials

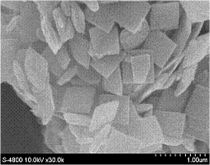

Zeolites, which are crystalline aluminosilicates that have pores of less than 1nm, have played vital roles in petrochemistry and catalytic chemistry. Zeolites have been synthesized conventionally by the method of precipitating crystals from a water solution (hydrothermal synthesis method). Meanwhile, we propose, and are researching, a new synthesis method called the dry-gel conversion (DGC) method. The Laboratory furthermore carries out research with the goal of developing a technique for creating thinner zeolite membranes as well as developing their applications as a separation membrane.

summary

■Research on micro- and mesoporous materials

A precursor gel is once dried, and this is then crystallized in the vapor phase. The use of the DGC method allows the preparation of zeolites with structures and compositions not obtainable by the hydrothermal synthesis method. The Laboratory conducts research on the crystallization mechanism of zeolite by the DGC method. Using the DGC or hydrothermal synthesis method, the Laboratory searches for microporous crystals with new structures, assesses catalyst characteristics, ascertains the crystallization process, and develops a method for inserting heteroelements into the crystal skeleton.

application/development

We are working to develop a new synthesis method for porous silica and for heteroelement-containing porous silica, as well as to develop a catalytic reaction in which uniform meso-pores manifest effective effects. We are also conducting research aimed at increasing the sophistication of catalyst functions by the hierarchical structuring of zeolite catalysts.

predominance

The DGC method allows the preparation of zeolites with structures and compositions not obtainable by the hydrothermal synthesis method. It has a technique for hierarchically structuring zeolite catalysts.

purpose of providing seeds

Sponsord research, Collaboration research, Technical consultation

remarks

■Awards: The Society of Chemical Engineers, Japan (SCEJ) Encouragement Award; The Japan Petroleum Institute Award for Encouragement of Research and Development; Catalysis Society of Japan Encouragement Award, The Japan Institute of Energy (JIE) Progress Award, etc.

■Affiliation: The Society of Chemical Engineers, Japan; The Japan Institute of Energy; The Japan Petroleum Institute; Japan Association of Zeolite; Japan Society of Energy and Resources; Catalysis Society of Japan; American Chemical Society; The Chemical Society of Japan; Materials Research Society; American Institute of Chemical Engineers; The Membrane Society of Japan

same researcher's seeds

-

Research into inorganic separation membranes

Research into inorganic separation membranes -

Development of cleaning agents for water and soil using inorganic materials

Development of cleaning agents for water and soil using inorganic materials

posted:

2014/05/21